Bgs General Srl – Pompe per vuoto – Vacuum Technology

RTM vacuum systems for vacuum infusion (resin transfer moulding), specially designed for resin infusion applications.

Resin vacuum infusion trap 24 lit.

Vacuum infusion trap equipped with: a transparent Plexiglas cover, manual vacuum relief valve, manual vacuum pump insulation valve, vacuum gauge.

Nominal pumping speed:

6 / 12 m3/h

Ultimate pressure:

0,5 mbar serie PBOM

| 50Hz (60Hz) |

Portata Nominale

|

Vuoto Finale

|

Potenza Motore

|

Giri Motore

|

Rumorosità

|

Capacità Olio

|

Peso

|

|

|

m3/h

|

mbar (a)

|

Kw – 3 ~

|

Kw – 1 ~

|

giri/min.

|

dB(A)

|

Litri

|

Kg

|

|

| 3 PBO |

3 (3,6)

|

10

|

0,11 (0,11)

|

0,11

|

2750 (3300)

|

57

|

0,1

|

7

|

| 3 PBOM |

3 (3,6)

|

2

|

0,11 (0,11)

|

0,11

|

2750 (3300)

|

57

|

0,1

|

7

|

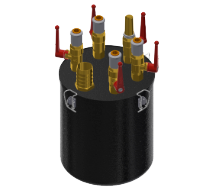

Resin vacuum infusion trap 6,5 lit.

Vacuum infusion trap equipped with 4 connections with valve and quick hose connection 12 mm, vacuum break valve and hose connector

for vacuum pump coupling. Opening lid for internal cleaning.

| 50Hz (60Hz) |

Portata Nominale

|

Vuoto Finale

|

Potenza Motore

|

Giri Motore

|

Rumorosità

|

Capacità Olio

|

Peso

|

|

|

m3/h

|

mbar (a)

|

Kw – 3 ~

|

Kw – 1 ~

|

giri/min.

|

dB(A)

|

Litri

|

Kg

|

|

| 6 PBO |

6 (7,4)

|

10

|

0,18 (0,18)

|

0,37

|

2750 (3300)

|

65

|

0,2

|

13

|

| 6 PBOM |

6 (7,4)

|

0,5

|

0,18 (0,18)

|

0,37

|

2750 (3300)

|

65

|

0,2

|

13

|

Resin vacuum infusion trap 95 lit.

Vacuum infusion trap equipped with: a transparent Plexiglas cover, manual vacuum relief valve, manual vacuum pump insulation valve, vacuum gauge.

Nominal pumping speed:

6 / 12 m3/h

Ultimate pressure:

0,5 mbar serie PBOM

| 50Hz (60Hz) |

Portata Nominale

|

Vuoto Finale

|

Potenza Motore

|

Giri Motore

|

Rumorosità

|

Capacità Olio

|

Peso

|

|

|

m3/h

|

mbar (a)

|

Kw – 3 ~

|

Kw – 1 ~

|

giri/min.

|

dB(A)

|

Litri

|

Kg

|

|

| 3 PBO |

3 (3,6)

|

10

|

0,11 (0,11)

|

0,11

|

2750 (3300)

|

57

|

0,1

|

7

|

| 3 PBOM |

3 (3,6)

|

2

|

0,11 (0,11)

|

0,11

|

2750 (3300)

|

57

|

0,1

|

7

|

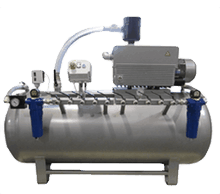

RTM vacuum system – 28 m3/hr.

The vacuum pump is assembled directly to the steel tank to reduce clearance requirements. The vacuum pump is equipped with a safety suction filter, non-return valve and shut-off valve. The electrical power panel and controls guarantee maximum efficiency; the pump can be started only if requested, thus reducing energy consumption to a minimum.

The tank features two vacuum outputs: the first output guarantees a maximum pump vacuum level, whereas the second output is equipped with a vacuum reducer for the final pressure adjustment and an active carbon filter.

In addition, the tank is equipped with casters to facilitate displacements inside the production site.

Nominal pumping speed:

28 m3/h

Ultimate pressure:

0,5 mbar serie PBOM

| 50Hz (60Hz) |

Portata Nominale

|

Vuoto Finale

|

Potenza Motore

|

Giri Motore

|

Rumorosità

|

Capacità Olio

|

Peso

|

|

|

m3/h

|

mbar (a)

|

Kw – 3 ~

|

Kw – 1 ~

|

giri/min.

|

dB(A)

|

Litri

|

Kg

|

|

| 6 PBO |

6 (7,4)

|

10

|

0,18 (0,18)

|

0,37

|

2750 (3300)

|

65

|

0,2

|

13

|

| 6 PBOM |

6 (7,4)

|

0,5

|

0,18 (0,18)

|

0,37

|

2750 (3300)

|

65

|

0,2

|

13

|

RTM vacuum system – 40/60 m3/h

The vacuum pump is assembled directly to the steel tank to reduce clearance requirements. The vacuum pump is equipped with a safety suction filter, non-return valve and shut-off valve. The electrical power panel and controls guarantee maximum efficiency; the pump can be started only if requested, thus reducing energy consumption to a minimum.

The tank features two vacuum outputs: the first output guarantees a maximum pump vacuum level, whereas the second output is equipped with a vacuum reducer for the final pressure adjustment and an active carbon filter.

In addition, the tank is equipped with casters to facilitate displacements inside the production site.

Nominal pumping speed:

40 / 60 m3/h

Ultimate pressure:

0,5 mbar serie PBOM

| 50Hz (60Hz) |

Portata Nominale

|

Vuoto Finale

|

Potenza Motore

|

Giri Motore

|

Rumorosità

|

Capacità Olio

|

Peso

|

|

|

m3/h

|

mbar (a)

|

Kw – 3 ~

|

Kw – 1 ~

|

giri/min.

|

dB(A)

|

Litri

|

Kg

|

|

| 3 PBO |

3 (3,6)

|

10

|

0,11 (0,11)

|

0,11

|

2750 (3300)

|

57

|

0,1

|

7

|

| 3 PBOM |

3 (3,6)

|

2

|

0,11 (0,11)

|

0,11

|

2750 (3300)

|

57

|

0,1

|

7

|

RTM vacuum system – 100 m3/h

The vacuum pump is assembled directly to the steel tank to reduce clearance requirements. The vacuum pump is equipped with a safety suction filter, non-return valve and shut-off valve. The electrical power panel and controls guarantee maximum efficiency; the pump can be started only if requested, thus reducing energy consumption to a minimum.

The tank features two vacuum outputs: the first output guarantees a maximum pump vacuum level, whereas the second output is equipped with a vacuum reducer for the final pressure adjustment and an active carbon filter.

In addition, the tank is equipped with casters to facilitate displacements inside the production site.

Nominal pumping speed:

100 m3/h

Ultimate pressure:

0,5 mbar serie PBOM

| 50Hz (60Hz) |

Portata Nominale

|

Vuoto Finale

|

Potenza Motore

|

Giri Motore

|

Rumorosità

|

Capacità Olio

|

Peso

|

|

|

m3/h

|

mbar (a)

|

Kw – 3 ~

|

Kw – 1 ~

|

giri/min.

|

dB(A)

|

Litri

|

Kg

|

|

| 6 PBO |

6 (7,4)

|

10

|

0,18 (0,18)

|

0,37

|

2750 (3300)

|

65

|

0,2

|

13

|

| 6 PBOM |

6 (7,4)

|

0,5

|

0,18 (0,18)

|

0,37

|

2750 (3300)

|

65

|

0,2

|

13

|

RTM vacuum system – 220/340 m3/h

The vacuum pump is assembled directly to the steel tank to reduce clearance requirements. The vacuum pump is equipped with a safety suction filter, non-return valve and shut-off valve. The electrical power panel and controls guarantee maximum efficiency; the pump can be started only if requested, thus reducing energy consumption to a minimum.

The tank features two vacuum outputs: the first output guarantees a maximum pump vacuum level, whereas the second output is equipped with a vacuum reducer for the final pressure adjustment and an active carbon filter.

In addition, the tank is equipped with casters to facilitate displacements inside the production site.

Nominal pumping speed:

220 / 340 m3/h

Ultimate pressure:

0,5 mbar serie PBOM

| 50Hz (60Hz) |

Portata Nominale

|

Vuoto Finale

|

Potenza Motore

|

Giri Motore

|

Rumorosità

|

Capacità Olio

|

Peso

|

|

|

m3/h

|

mbar (a)

|

Kw – 3 ~

|

Kw – 1 ~

|

giri/min.

|

dB(A)

|

Litri

|

Kg

|

|

| 3 PBO |

3 (3,6)

|

10

|

0,11 (0,11)

|

0,11

|

2750 (3300)

|

57

|

0,1

|

7

|

| 3 PBOM |

3 (3,6)

|

2

|

0,11 (0,11)

|

0,11

|

2750 (3300)

|

57

|

0,1

|

7

|

RTM dual tank vacuum system.

The vacuum pump is assembled onto a steel base, combined with two vertical tanks. The vacuum pump is equipped with a safety suction filter, non-return valve and shut-off valve. The electrical power panel and controls guarantee maximum efficiency; the pump can be started only if requested, thus reducing energy consumption to a minimum.

The first tank guarantees a maximum pump vacuum level, whereas the second tank is equipped with a vacuum reducer for the final pressure adjustment and an active carbon filter.

Nominal pumping speed:

40 / 60 / 100 / 220 / 340 m3/h

Ultimate pressure:

0,5 mbar serie PBOM

| 50Hz (60Hz) |

Portata Nominale

|

Vuoto Finale

|

Potenza Motore

|

Giri Motore

|

Rumorosità

|

Capacità Olio

|

Peso

|

|

|

m3/h

|

mbar (a)

|

Kw – 3 ~

|

Kw – 1 ~

|

giri/min.

|

dB(A)

|

Litri

|

Kg

|

|

| 6 PBO |

6 (7,4)

|

10

|

0,18 (0,18)

|

0,37

|

2750 (3300)

|

65

|

0,2

|

13

|

| 6 PBOM |

6 (7,4)

|

0,5

|

0,18 (0,18)

|

0,37

|

2750 (3300)

|

65

|

0,2

|

13

|