Bgs General Srl – Pompe per vuoto – Vacuum Technology

BGS General provides a wide selection of accessories to satisfy every need.

Air Filters – Lubricant fluids – Vacuum breaker valves – Measuring instruments and vacuum control – Connectors – Oil level switches – Vacuum regulators – Solenoid Valves – Pressure and vacuum switches – Vacuum tanks – Silencers – Liquid and powder separators – Vacuum control valves.

Suction filters

Filters are used to protect the vacuum pump from solids or powders that can damage the pump.

We offer different types of filtration based on the type of application:

FCV:

Filter with paper cartridge

– degree of filtration: 15 μ

– attachments: from 3/8 3 G to 3 3Gas

FMV:

Filter with metal cartridge

– degree of filtration: 60 μ

– attachments: from 3/8 3 G to 3 3Gas

FOP:

Filter with oil bath

– degree of filtration: ≤1 μ

– aattachments: from _ 3 G to 3 3Gas

Liquid separator filters

BGS GENERAL offers different solutions to protect vacuum pumps from liquids, sludge or process particles.

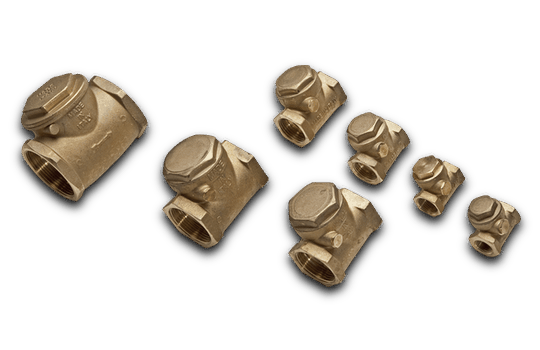

Check valves

Unidirectional valves to apply to the vacuum pump suction to guarantee the vacuum seal and/or prevent oil reflux from the vacuum pump to the system.

Materials:

Bronze and brass – seals in rubber NBR/Viton/Teflon.

Attachments:

from 3/8″ Gas to 4″ Gas

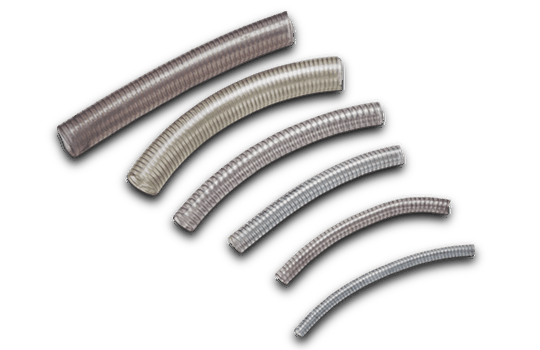

Vacuum tubes

Tubes in reinforced PVC with a harmonic steel spiral suitable for connecting the vacuum pump suction to the system.

Can also be used to convey the vacuum pump discharge.

Diameters:

from 1/2″ Gas to 3″ Gas

Operating temperature:

-50 °C +65 °C.

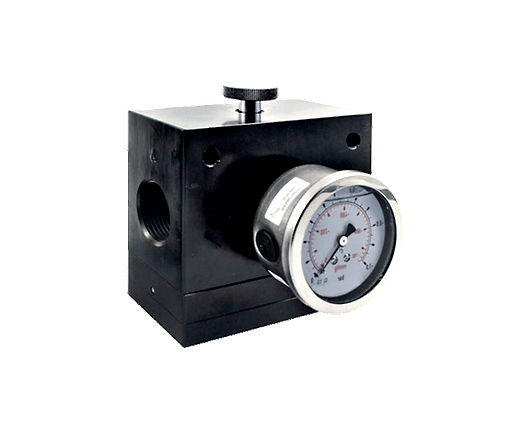

Vacuum regulator

Used to regulate the degree of vacuum and maintain it constant regardless of the pump capacity and vacuum oscillations. To regulate the degree of vacuum, no air is input into the circuit, allowing for the use of several vacuum reducers, connected to the same source, creating different uses with different degrees of vacuum.

Adjustable operating pressure:

from 650 to 1 mbar ass.

Capacity:

up to 160 mc/h.

Vacuum Switches – Pressure Switches

The vacuum switch – pressure switch is used to start / stop of the vacuum pumps / compressors.

The electric contact switches according to the vacuum / pressure detected by the instrument.

Ability to adjust the pressure for action and hysteresis.

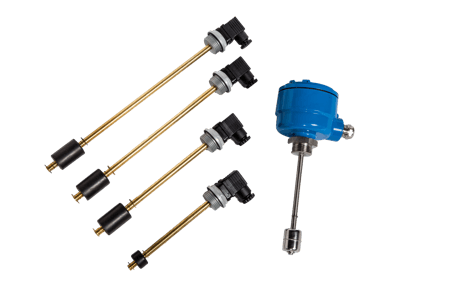

Oil level Switches

Float switches with a permanent magnet for measuring the oil level.

Used to monitor the lubrication oil level on the vacuum pump and send an alarm in the event of a

lack of oil or low oil level.

Atex versions available.

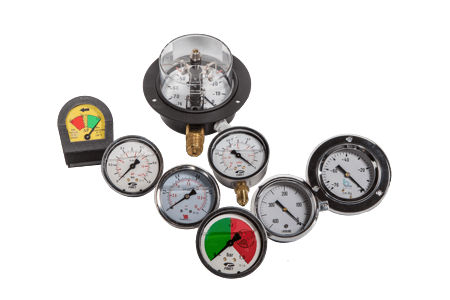

Vacuum Gauges – Pressure Gauges

Vacuum Gauges in glycerin bath for the measurement of the vacuum.

Pressure Gauges in glycerin bath for the pressure measurement.

Available in different configurations and reading scales.

ON/OFF electrical power and control panel

ON/OFF power and control panel consisting of a plastic box equipped with thermal protection for

the electric motor, power button and stop/emergency button.

Can be used simply for switching the pump on/off or, with a mechanical vacuum switch to manage

starting and stopping completely automatically based on the pressure and hysteresis set on the

vacuum switch.

Can manage pumps with a single or three phase motor up to 7.5kw.

DIGITAL electrical panel for 2 pumps

The new BGS GENERAL control panel is specially designed to manage vacuum pumps, providing

a high level of technology and significant flexibility in managing all the necessary information for

properly operating vacuum systems.

The Display allows for the monitoring and editing of all settings based on the desired operation.

Main features:

– Automatic control and optimization of energy consumption for each individual pump, with

programmable automatic interchanges.

– Alarms display (no vacuum – low oil level – pump blockage – etc.)

– Configurable number of pumps connected

– Programmable On/Off thresholds for each individual pump

– Configurability of minimum vacuum threshold for alarm generation

– Management and display of operating hours counter for each individual pump

– Display of scheduled maintenance operations for each individual pump

– Automatic and manual operation..

– Alarms management via remote using clean contacts

DIGITAL electrical panel for 2 pumps + Emergency pump

The new BGS GENERAL control panel is specially designed to manage CE certified

MEDEVICE vacuum control units for medical applications.

The electrical panel consists of two sections, as required by the standard UNI EN7396:1,

guaranteeing maximum safety in all emergency situations.

The display allows for the monitoring and editing of all settings for optimum vacuum control

management.

Main features:

– Automatic control and optimization of energy consumption for each individual pump, with

programmable automatic interchanges.

– Programmable pump start management to limit electrical absorption peaks.

– Alarms display (no vacuum – low oil level – pump blockage – required maintenance, – etc.)

– Number of pumps connected configurable up to 4 pumps

– Programmable On/Off thresholds for each individual pump

– Configurability of minimum vacuum threshold for alarm generation

– Management and display of operating hours counter for each individual pump

– Display of scheduled maintenance operations for each individual pump

– Automatic and manual operation.

– Alarms management via remote using clean contacts

– Alarms management and system information via MODBUS PROTOCOL

– Management of pumps with a single and three phase motor

Manual 2-way valves

Manual ball valves normally used to isolate the vacuum pump from the production plant.

Materials:

Nickel-plated brass – brass ball chrome – Teflon seals.

Attachments:

from 1/4″ Gas to 4″ Gas